Forklifts

What Are The Different Types of Forklifts?

October 11, 2022

Forklifts, also known as lift trucks, are necessary piece of equipment that boost your warehouse or job site productivity by allowing you to easily lift, stack and transport mass quantities of products or materials. But choosing the right type of forklift to meet your needs isn’t always as easy as it may seem. Forklifts and lift trucks come in many different shapes, sizes and types. While each type of forklift is designed with different capabilities, they’re all essential to efficiently and effectively getting the job done. You’ll need to know the different types of forklifts and what the capabilities of each are before settling on the right one for your warehouse or job site.

The Versatility of Forklifts

Before we dive into the different forklift names and their capabilities, it’s important to understand the versatility and importance of forklifts for your business, warehouse or job site. Forklifts and lift trucks serve a multitude of purposes across a range of different industries including:

- Warehouse operations

- Storage and moving

- Supply management and material delivery

- Construction sites

- Grocery and retail stores

These are just a few of the industries that rely on forklifts to efficiently manage their day-to-day operations. Whether it’s loading and unloading trucks or stacking and picking warehouse products, forklifts are versatile pieces of equipment.

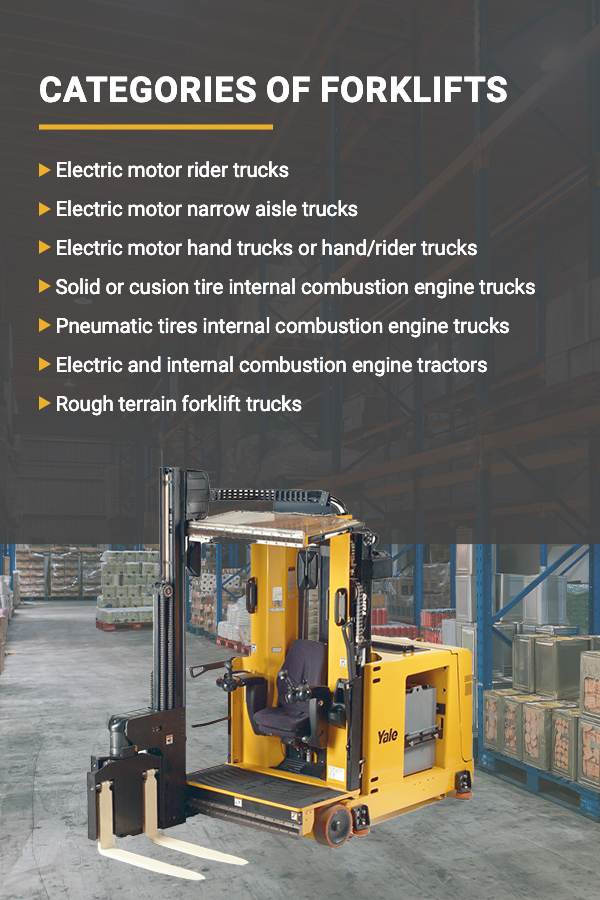

Categories of Forklifts

Forklifts and lift trucks are designed for different tasks and environments. Some forklifts are designed for indoor settings where air quality is a priority while others are meant to be used outdoors on construction sites. Likewise, some forklifts feature long arms designed to reach areas that are higher up and others are engineered to fit in small, narrow spaces where maneuverability is limited. Forklifts generally fall into one of seven categories:

- Electric motor rider trucks

- Electric motor narrow aisle trucks

- Electric motor hand trucks or hand/rider trucks

- Solid or cushion tire internal combustion engine trucks

- Pneumatic tires internal combustion engine trucks

- Electric and internal combustion engine tractors

- Rough terrain forklift trucks

These are the 7 most common types of forklifts and lift trucks that you’ll find on the market. While there are many different types of forklifts, most all of them fall into one of the 7 categories outlined above. Learn more about some of the different types of forklifts and what tasks they’re designed to handle below.

Different Types of Forklifts

Forklifts are designed to quickly, safely and efficiently lift and move products or materials around your warehouse or job site. Forklifts can be customized to meet your unique needs, and it’s not uncommon to blend the capabilities of different types of forklifts to create the ideal piece of equipment that gets the job done. The right type of forklift can serve a multitude of purposes, saving you time and money.

If you’re not sure which forklift best suits your needs, then here’s a breakdown of some of the different types of forklifts and their capabilities.

1. Very Narrow Aisle Trucks

Very narrow aisle trucks are the ideal type of forklift for high-density warehouses and worksites. These compact pieces of equipment make it possible for operators to maximize productivity when maneuvering around tight spaces.

Warehouses organized to maximize their space can challenge efficiency. This type of forklift helps you maintain performance, despite the close quarters that could slow you down with a bulkier piece of equipment. Its compact size accommodates a stand-up design and reduces its turning radius.

Distribution centers that need to make the most of every cubic foot of their warehouse can benefit from a very narrow aisle truck that allows operators to reach new heights for storage. When reaching high elevations, narrow aisle trucks provide a great deal of stability.

Another advantage of this type of forklift is its safety. Larger forklifts can endanger the operator if they bump into warehouse structures. Thanks to their small design, these trucks reduce the risk of running into items around the warehouse.

2. Electric Forklifts (4-Wheel)

4-wheel electric forklifts have a sturdy base and work great for lifting heavy loads. These pieces of equipment work best for uneven terrain and bulky loads that are hard to turn or maneuver.

There are various types of 4-wheel forklifts with different tires and lifting capacities. Some common types of forklifts designed with four wheels include:

- Counterbalance

- High-capacity

- Side loader

Their design makes them ideal for lifting cumbersome loads while maintaining balance and stability.

You’ll want a 4-wheel forklift if you deal primarily with outdoor environments and bulky palletized loads, or if you need to access high shelves and spaces. They are designed to be balanced and durable.

3. Electric Forklifts (3-Wheel)

3-wheel electric forklifts are designed similarly to a tricycle with two wheels on one end and a single wheel on the other. These pieces of equipment are excellent for maneuvering tight, narrow spaces where the turning radius shrinks.

There are different types of 3-wheel forklifts, such as stand-up rider forklifts and order picker lift trucks.

3-wheel forklifts are defined by their maneuverability and ability to maintain productivity levels while working in tight spaces. Their compact design makes them ideal for applications including:

- Retail stores

- Agriculture

- Wholesale distribution centers

4. Pallet Stackers

Pallet stackers function as mobile pallet jacks and make it possible to stack pallets in confined spaces. These pieces of equipment make it possible to position loads with accuracy and versatility.

Warehouses dealing with high volumes or medium-sized items can benefit from pallet stackers, as they make the following easier:

- Lifting

- Stacking

- Transporting pallets

These small, maneuverable forklifts are a great investment in your company’s future, as they have a range of uses. Pallet stackers are flexible and adaptable enough to meet your company’s changing needs, such as if your warehouse must suddenly handle new products.

They’re also affordable, easy to maintain and more straightforward to use than larger mechanical equipment.

5. Electric Pallet Trucks

Pallet trucks are electric motor rider trucks or hand trucks with two long forks that easily slide under a palletized load.

These trucks are designed to move palletized loads for applications in industries such as:

- Cold and frozen food

- Retail fulfillment

- Auto parts distribution

- Furniture

These forklifts can quickly maneuver indoor environments where you need to move palletized loads without sacrificing air quality.

Pallet trucks are sometimes confused for hydraulic skates, but they tend to possess more capabilities and features than skates. Some pallet trucks have the ability to lift and move more than one palletized load at a time to boost labor efficiency.

Pallet trucks come in different shapes and sizes, ranging from simple designs meant to grab one small palletized load to stand-on electric rider trucks for heavier lifting.

They are capable of lifting and transporting multiple bulky loads. Pallet trucks are indoor forklift options that are versatile and easy to use.

6. Reach Trucks

Reach trucks are designed with an extended lifting mechanism that’s able to reach higher than traditional warehouse forklifts. This type of forklift is an excellent option for tall and tight warehouse bays where loads are stored.

Reach trucks sometimes feature tilting lifting mechanisms that allow you to lean your forks slightly forward to grab hard-to-reach pallets and loads.

They are typically designed with four wheels for balancing heavy loads in high places. However, some reach forklifts are designed with three wheels for better maneuverability in and out of tight, narrow aisles. Some of their benefits include:

- Flexibility

- Boosted productivity

- Precise control

7. High Capacity Cushion Tire Forklift Trucks

High capacity cushion tire forklift trucks are meant for heavy lifting in indoor industrial applications. Their tires are ideal for smooth surfaces like warehouse floors.

These trucks have amazing lifting capacities paired with great stability and maneuverability.

Multiple industries use high capacity cushion tire forklifts because they are so versatile. One of the greatest benefits of this equipment is its ability to use various mast, fork and carriage combinations.

High capacity cushion tire forklifts include:

- A heavy-duty steel frame with stacked counterweights.

- Standard knuckle steering for a tighter turn radius.

- A wide, upright mast for precise loading and maximum visibility.

- Drive axle with force brake cooling and wet disc brakes.

- Cushion tires for improved outdoor use and use on rough or uneven terrain.

- Easy maintenance, with a removable cab and easy-to-reach engine, hydraulic system and transmission.

8. High Capacity Forklift Trucks

High capacity forklift trucks are designed to handle the heaviest and bulkiest of loads while maximizing productivity.

With the ability to lift over 20,000 pounds, high capacity forklifts are excellent options for the following applications where extremely heavy items are packaged and shipped:

- Industrial supplies

- Produce farmers

- Forestry

- Concrete materials

- Paper mills

High capacity forklifts resemble tractors and generally come with four wheels that provide balance and a solid base to handle heavy workloads.

9. Compact Internal Combustion Trucks

Compact internal combustion trucks have high capacities for doing the following while maintaining productivity:

- Lifting

- Stacking

- Towing

Some of the most common industries that utilize this type of forklift include:

- Paper products

- Warehouses

- Light manufacturing

- Transporters

- Building materials

- Metals

- Trucking

- Health and pharma

Compact internal combustion trucks are highly versatile and have a high load capacity. These pieces of equipment also benefit from their internal combustion engines because the heat loss is lower, making them ideal for indoor applications.

Because of their small dimensions, these forklift trucks can keep your operation efficient, even when handling cumbersome loads.

10. Order Picker Forklifts

As their name suggests, order picker forklifts are designed to quickly maneuver large warehouses and grab orders from various heights.

Order pickers are also known as cherry pickers or order selectors. These pieces of equipment have the capability to handle small individual boxes or large palletized loads with medium and high-lift abilities. They are built to be a diverse warehouse vehicle that can reach:

- High shelves

- Deep bays

- Narrow aisles

Order pickers are typically stand-on forklifts and are designed for you to quickly jump on and off while filling warehouse orders.

11. Internal Combustion Pneumatic Tire Trucks

Internal combustion pneumatic tire trucks are a type of forklift suitable for indoor and outdoor applications that require medium- to heavy-duty lifting.

Industries such as the following can benefit from these pieces of equipment:

- Lumber

- Mining

- Construction

- Energy

- Rental stores

- Paper

Known for their versatility and durability, these types of forklifts make it possible to tackle many types of lifting jobs, and they are available with different attachment options.

YIT Inc Carries a Wide Range of New and Used Forklifts

YIT, Inc proudly carries a wide range of new and used forklifts to fit your budget. With four locations in London, Ontario, Woodbridge, Burlington Ontario and Montreal Quebec, YIT is your one-stop shop for forklifts and other industrial equipment to meet your material handling needs.

For over 40 years, YIT has offered dedicated forklift sales, service and support to the businesses and industries that call Ontario and Quebec home. Need equipment for a short-term project or job? No problem! Our experienced rental team is standing by to help get you all the equipment you need to get the job done on time!

In addition to renting, selling and servicing forklifts and other industrial equipment, YIT offers forklift training courses to upskill your team members and keep you moving forward. Ready to learn more about our line of products and training services? Give us a call toll-free or fill out an online contact form to learn more about YIT line of forklifts, products and other services!